3-point bending test pdf|3 point bending test calculator : consultant The present lab session deals with a three-point-bending test to obtain the following material parameter. Stress vs. engineering strain curve and stress vs. real strain curve. Flexural . webReceba o seu código Americanas por email imediatamente. Selecione o valor do gift card que quer comprar, escolha um dos mais de 63 métodos de pagamento seguro e pronto! Logo após o pagamento, você verá o código no seu computador. Você também receberá um email com o código, o recibo e as instruções para usar o código.

{plog:ftitle_list}

ed junior fode uma branquinha gostosa sem tirar o shorts jeans e sem camisinha)(completo no red e no sheer) 9.5k 83% 6min - 1080p Branquinha casada levando gozada no cú.

three point bending test standard

THREE-POINT BENDING TEST PROCEDURE: RECTANGULAR CROSS SECTION. Determination of the stiffness (compliance) of the testing system: Ks (Cs). The test is carried .Example 1: Rectangular Three Point Bending A rectangular specimen is subjected to a three-point bending test. The specimen is 10 centimeters long, 10 millimeters wide (b) and 10 .The present lab session deals with a three-point-bending test to obtain the following material parameter. Stress vs. engineering strain curve and stress vs. real strain curve. Flexural .

In the case of orthotropic materials like wood or composites, transverse shear has an effect on the modulus determination by bending tests. A procedure based on three-point bending is.

Bone Mechanical Testing by Three-Point Bending. In a three-point bending test, the whole bone is placed in a fixture attached to a materials testing machine and loaded until broken .

3-point bending test: It produces its peak stress at the material mid-point and reduced stress elsewhere. 4-point bending test: It produces peak stresses along an extended region of the . The two common types of bend fixtures are three-point and four-point bend fixtures: (1) Three-point bend fixtures: Configuration of flexural strength testing where a specimen is loaded at a.Abstract: This guide is intended to aid the establishment of good practice in flexural testing of beam test-pieces of non-ductile materials, especially ceramics and hardmetals, whether or .

Closed form equations for analyzing or reducing data from a three-point-bend test (fig. 1) are described herein. The equations are for shift of the neutral plane (zero bending stress plane), ma.ximumum bending deflection, flexural (bending) modulus, shear modulus, maximum bending stress, and maximum shear stress. Only the final

Place the test bar on the 3 point bend fixture and begin the test and end after bending to 5% deflection or until the sample breaks. Tips: Testing speed: The speed of the test is very slow and variable depending on the support span .Single-edge notch-bending specimen (also called three-point bending specimen) for fracture toughness testing.. The fracture toughness of a specimen can also be determined using a three-point flexural test. The stress intensity factor at the crack tip of a single edge notch bending specimen is [3] = [() / / + / / + /] where is the applied load, is the thickness of the specimen, is .

1.1 These test methods are used to determine the flexural properties of unreinforced and reinforced plastics, including high modulus composites and electrical insulating materials utilizing a three-point loading system to apply a load to a simply supported beam (specimen). The method is generally applicable to both rigid and semi-rigid materials, but .Mach-1 – 3-point or 4-point Bending Test MA056-SOP11-D v1 BMMT CC#2016-001 BMMT QF4.02.01 v1 CONFIDENTIAL - UNCONTROLLED UNLESS OTHERWISE SIGNED AND/OR STAMPED Page 5 / 9 For the 3-point bending setup: For the 4-point bending setup: Note 1. For the 4-point bending top fin, it is necessary to adjust the distance between the two2.3.4. Four-point bending test. Four-point bending tests were conducted on the PVA-ECC beams using the 200 kN Tecnotest Flex machine in accordance with standard ASTM C1609 (ASTM, 2006). Instead of three-point bending tests, four-point bending tests were performed so as to investigate the flexural behavior in the pure bending region.A three-point bend test applies force at the midpoint of a rectangular specimen, which is freely supported at either end. The applied force is measured by a load cell, and the resulting deflection is measured by either the system’s crosshead displacement (with results corrected for system compliance) or by a direct strain measurement device .

remember to wear goggles (provided) during each test. 3 Point Bending Test Choose the 3pntBME315 or another bending method from the computer menus. You will indicate to the computer that you will use a new sample each time. Enter the necessary measurements prompted by the computer (i.e. width and thickness of the specimen, rate of the test, The instrumented 3-point bending test according to VDA238-100 test standard is increasingly used within the steel and automotive industry. Originally developed for aluminum hemming .

three point bending test setup

Like the 3-point bending test, 4-point bending test and the cantilever bending test are other techniques that can be used to study the flexural stress of materials. In particular, if the material is not homogenous, ie. composites, the 4-point bending test provides a more complete study of the stress behaviour by increasing the loading region ona mouse femur bending test. The portion of the curve to the left of the yield point represents the elastic behavior of the bone. If you release the load before reaching the yield point, the bone springs back to its original shape like an elastic band. To the right of the yield point represents the post-yield (or plastic) behavior.Annex B) shall be maintained for test pieces greater than 3 mm thick, then the bend test shall be carried out in accordance with Annex B. 7.4 Thickness of the test piece 7.4.1 The thickness of test pieces from sheets, strips and sections shall be equal to .3-point flexure test kit for small plate bending test on metallic mate‐ rials Distance gauge for standard compliant positioning of the flexure test kit PI 345 1223 Applications The VDA 238-100:2020-07 is the basis for the test arrangement. This 3-point flexure test kit is used to perform small plate bending tests for determination of

bending test. A three-point bending test is known methods used to evaluate the strength and stiffness of a beam [13,14]. To conduct a three-point bending test, a testing rig needs to be employed. The main function of the testing rig is fixing the specimen horizontally and applying load on the middle span of the specimen [15]. Commonly, bending .

Three-Point Bend Testing: 1) Prepare two similar wooden bar specimens for a three-point bending test. 2) The two specimens should have the same initial dimensions, so use the Vernier Caliper or another suitable measurement tool .This test setup includes a 3400 Series test system with a 3-point bend fixture and no extensometer, meaning that strain in this case must be measured by crosshead displacement (Type 1 testing). Whenever strain is measured via .a bending stress value per unit area with Equation 1. 2 2 3 bh PB L σfb = (Equation 1) Although SEMI has also defined G96-1014 [2] as the standard of cantilever bending test, the more commonly used 3-point bending test was employed in this review. 3. Evaluation results 3.1 Influence of saw marks As mentioned above, due to grinding during 1.1 These test methods cover bend testing for ductility of materials. Included in the procedures are four conditions of constraint on the bent portion of the specimen; a guided-bend test using a mandrel or plunger of defined dimensions to force the mid-length of the specimen between two supports separated by a defined space; a semi-guided bend test in which the .

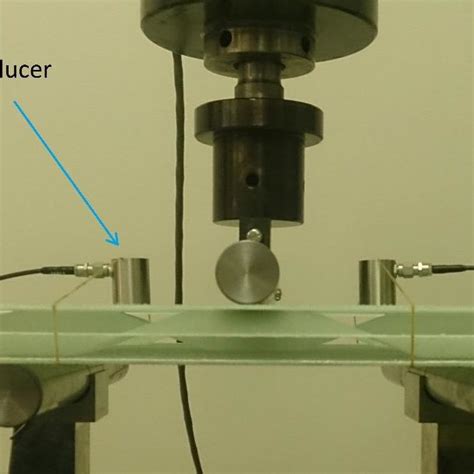

The document describes a three point bending test experiment conducted in the Mechanical Engineering laboratory at Yeditepe University. The experiment aims to introduce students to three point bending tests and measure a specimen's mechanical properties using strain gauges. A beam specimen is placed on supports and loaded by a force at its midspan in an Instron . In a recent study [11], a new method for investigating the size effect on the bending behavior of small-sized specimens cut from wood and veneer has been developed based on the three-point bending .

The document introduces the three point bending test used to measure the mechanical properties of specimens through strain gauges. Key steps include: 1) Mounting a specimen in a three point bending fixture on a universal testing machine. 2) Attaching strain gauges to the specimen and connecting them to a Wheatstone bridge and data acquisition system. 3) .Easy to install, the 3-point fixture can be modified with an optional conversion kit to provide a 4-point bending conversion. Lower anvils are adjustable to accommodate specimens of different spans. Deflection of the specimen can be measured either through crosshead displacement, or for more precise measurement you can use a mid-span direct .Bending strength is defined as a material's ability to resist deformation under load, it represents the highest stress experienced within the material at its moment of rupture. There are two types of bending tests. Three point bending test and four point bending test. In a three point bending test the area of uniform

For the high velocity three-point bending test, an instrumented impact drop tower equipped with an insert of a given shape attached to the tup can be used. The specimen is suspended on two cylindrical supports and the insert strikes it in its center. During the impact, the load is recorded by the sensor (piezoelectric or strain-gauge) embedded .

3 Point Bending-1 - Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. The document describes a three point bending test experiment. Three point bending tests are used to evaluate the strength of brittle materials. In a three point bending test, a load is applied at the midspan of a rectangular test specimen, which is supported on both ends.

The test program consisted of 11 three-point bending tests and 11 four-point bending tests. The test specimens were fabricated by extrusion using 6061-T6 heat-treated aluminium alloy, and had .The three standard bending strength tests are the cantilever beam bend test, the three-point bend test, and the four-point bend test. European Standard EN 12384 specifies a bend test to determine the modulus of elasticity in bending. Japanese Industrial Standard JIS 3130 specifies two tests to determine the elastic limit of spring plate or .

212, 332, 646 e 917. Harlem é um bairro de Manhattan, na cidade de Nova Iorque, conhecido por ser um grande centro cultural e comercial dos afro-americanos. Apesar de o nome ser geralmente atribuído a toda a região .

3-point bending test pdf|3 point bending test calculator